Hydroponic farmer Aaron Thormodsen inspects a tray of plants being grown at the hydroponic farm on WesleyLife’s new Meals on Wheels campus in Des Moines. Photo: Duane Tinkey

Writer: Sarah Diehn

Whether it’s on a local or global scale, finding, developing and implementing solutions for food insecurity requires innovative thinking.

Two new projects in Central Iowa — the Prairie Meadows Hydroponics Farm at the new WesleyLife Meals on Wheels campus and Iowa State University’s Kent Feed Mill and Grain Science Complex — focus on agricultural methods that make food last longerlonger lasting or more nutritious.

The leaders of both projects recently explained how their approaches work. Their Q&A responses below have been edited and condensed for clarity and brevity.

Hydroponics: salads grown without soil

WesleyLife built an indoor hydroponic farm at its new Meals on Wheels campus in Des Moines to increase the nutritional quality of the 2,000 meals it delivers to older adults every day.

A hydroponic system provides plants with ideal conditions for fast growth, said Aaron Thormodsen, WesleyLife’s hydroponic farmer. “We have optimal temperature, optimal humidity, optimal nutrients, water levels, oxygen levels,” he said. “We make it so these plants can grow as fast as they physically can.”

With that speed, the plants can yield several harvests over their lifespan. The farm currently grows six varieties of leafy greens, which produce about 100 pounds of food per week, Thormodsen said.

The greens are distributed through Meals on Wheels deliveries and WesleyLife’s senior living communities, as well as Hugo’s Wood-Fired Kitchen, the restaurant Lynn Pritchard opened in May in the same building. The greens have been served in 20,000 meals in the last six months. Shannon Draayer, WesleyLife’s executive director of community nutrition, said her team plans to develop retail partnerships to help offset the farm’s costs.

As the hydroponic farm expands, Thormodsen hopes to harvest up to 150 pounds of greens each week by streamlining the processes for seeding, transplanting, cleaning and harvesting. He answered the following questions about hydroponics.

So what is hydroponics and how does it work?

Broadly speaking, hydroponics involves growing plants in water. The water provides all of the nutrients and the correct growing environment so the plants can pick up those nutrients. That means proper levels of dissolved oxygen and pH.

Generally speaking, hydroponic systems are recirculating. There’s a reservoir down below, which connects up to a pump that goes up to ball valves. The ball valves then drop water into these legs, which allows the water to flow down in a zigzag all the way down to a drain line that empties back to the reservoir.

We also pretreat the water. Des Moines water has minerals in it that are fine for a human, but in a hydroponic system where water gets concentrated, minerals like chlorine and sodium can become toxic to plants really quickly. We have a reverse-osmosis system where the water is prefiltered and then pumped into our reservoirs to refill them. We use a mixture of hydroponic nutrients, and there’s a part A and a part B, which allows us to balance the right amount of each nutrient.

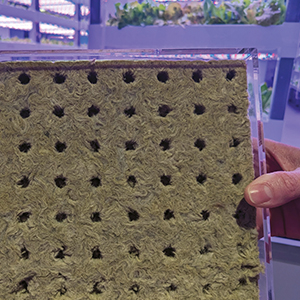

Even with hydroponics, plants still have to root into something, so we use a soilless material called rockwool, which is a man-made stone wool. We’re also testing an organic peat moss sponge, and if that goes well, we’ll switch over to it so eventually we can compost the root systems.

Water flows in a zigzag all the way down to a drain line that empties to the reservoir at the bottom. The water reservoir connects to a pump that sends water up to ball valves to be cycled through again.

Hydroponic plants require a specific mixture of nutrients that are applied in two parts to get the right balance.

Rockwool, a man-made stone wool that plants are rooted into.

How do the lights help the plants grow?

That’s its own Ph.D. study. Indoor grow lights are just a wild concept because we’ve essentially flattened the sun and brought it indoors. Broadly speaking, plants absorb all frequencies of light. Since most plants are green, they’re reflecting green and absorbing red and blue. But research shows that plants do like to pick up that green frequency. It’s more efficient, and they grow faster under that. Plants grow more roots in a blue spectrum, so if you’re growing young plants, you want to encourage root growth so the plants are heartier later in life. That’s why the germinating plants are under blue light. Older plants are under white and red light because the red spectrum induces faster growth. So it’s not that we’re just taking the sun and bringing it inside; we’re trying to make the sun more effective for specific types of plant growth.

Blue, white and red lights are used at different times in a plant’s life cycle to help them grow faster.

How does hydroponic farming make food better or more plentiful?

Hydroponics is efficient in a couple different ways. The space usage is efficient in two ways: It’s vertical, but there’s also a higher density that you can’t really do in a traditional field. Plus, our product tastes better; that’s the truth of the matter. It’s not crunchy water. People want food that has flavor, and our product has a more tender texture and a better flavor. If you’re really trying to get folks to eat healthy, you have to provide a product people want to eat.

WesleyLife Chief Operating Officer Allison Pendroy helps with a harvest on the farm.

How else is hydroponics different?

In traditional agriculture, crops grow on the same soil year after year. Even with minor crop rotations, you’re still depleting the soil. So to keep growing salad greens in spaces like Salinas, California, and Yuma, Arizona, farmers grow varieties that can handle stress and pests, and they use automation. Handling and harvesting can be very difficult on greens, which can lose nutrients in the process. So farmers try to make sure their crops grow big and green and fast.

Hydroponics can’t work that way because we don’t have soil. We have to provide all the micronutrients the plants use, like 15 to 17 different nutrients. We know that only through hydroponics, because if something isn’t growing right, we can observe it and try to figure out what’s missing. By providing those additional nutrients, plants can grow those more complex phytonutrients that translate into healthier food.

What kind of plants can grow hydroponically?

Literally everything. The first farm I worked on was a research farm, where we grew everything from lettuce to fava beans to cauliflower to lemon trees. The reason why we’re growing mostly leafy greens is partly because they’re a nicer and easier product to start with. It’s consistent. There’s an easy market for it. The kitchen wants it and folks know how to use it.

Another reason we grow leafy greens is because it’s efficient. Energy converts directly into pounds of food. If you’re growing tomatoes, you may get 3 pounds off of a plant every week during the season, but the total biomass of that plant is 10 times that, and when you’re using indoor grow lights, that means your power usage is going to parts of the plant that you’ll never use. A lot of this is about efficiency.

Grain science: seeding global knowledge

Even as Iowans zoom in on local food security, the state is also helping to feed the world.

Harvested grains like corn and soybeans need to be properly handled and stored so they don’t spoil. Keeping the grain dry and cool is a big part of “post-harvest engineering” methods.

Dirk Maier, an Iowa State University professor and director of the ISU Kent Feed Mill and Grain Science Complex, said Iowa works with countries in Central America, Africa and Asia to improve post-harvest practices and find affordable technologies and methods to preserve grain.

He said when farmers lose portions of their harvest, it affects what food farmers have to feed their families and animals. For example, an African farmer who loses some of the yellow corn used to feed animals will have to give the animals white corn, which Africans usually grow for human consumption.

Maier and his colleagues travel worldwide to help farmers. But with the new grain science complex, which opened in Ames in fall 2023, they can also host international visitors for education and research. The complex also serves agriculture students closer to home.

“Our focus is on people,” Maier said. “Ultimately, we can make an impact in terms of lives and livelihoods in different places of the world. All the technology and all the science is fantastic and we love it, but it’s really about how we help the next generation of people who are affected right now with being able to adapt, adopt and apply the knowledge and techniques and technologies that we’re already aware of.”

The Iowa State University Kent Feed Mill and Grain Science Complex in Ames provides a facility to train students and host international visitors for research and education.

What does corn require after the harvest?

The key challenge with corn at harvest time is its moisture content and its initial quality. When we think about moisture content, corn in Iowa may be harvested at anywhere from 18% to 25% moisture content, and that range of moisture content is generally not safe for storage without the additional step of drying the corn, typically on a farm or an elevator with high-capacity drying systems. We bring that moisture content of the corn down to 14% or 15%, depending on the length of storage. If you don’t dry the corn, it can spoil as a result of mold. And that spoiling will destroy its value, both in terms of quantity and quality of that corn. It’s the same with other grains, too.

How does post-harvest engineering support global food security?

Iowa weather is pretty conducive to producing as well as preserving and protecting grains. When you get into the export market, grains like rice and wheat are primarily used for human food, and corn is used for animal feed. But in Central and South America, sub-Saharan Africa and Southeast Asia, corn is also used for human consumption, so it’s a lot more critical to preserve it for the longer term. They produce corn in those countries, as well, but typically not enough for self-sufficiency. Typical losses on grains in those countries are 20% to 25% post-harvest, as a result of poor post-harvest management practices and the costs of post-harvest technologies.

How do better technology and techniques help with food security?

When you think about smaller producers, if they have a bad crop and can only harvest, say, five bags, but their family needs eight bags to make it to the next harvest, they’re going to get into a hunger season. They may or may not be able to afford buying those extra three bags. When they have better practices, better techniques and technologies, they can feed themselves with what they’ve grown. That may not necessarily be the best nutritional mix, eating just corn, but it supplies the calories and energy.

What role does Iowa play in grain science? And how do you think that will evolve?

Iowa plays a huge role. If Iowa was a country, we’d rank fourth in the world as a corn producer: the U.S., China, Brazil, Iowa. We add a huge amount of value to our corn by converting it into animal source protein, into ethanol and so forth. From an agri-industrial perspective, we can set a good example. We can also demonstrate how to farm in ways that help the environment and how to do that in a more sustainable manner.

We provide a lot of help with technical assistance training. We go overseas. We just had groups from East and West Africa at the complex for training last month. We have four fellows coming from four different African countries for three months to study with us. We look at the ISU Kent Feed Mill and Grain Science Complex as a global player.

When you interact with industry people from all over the world, there’s always interesting questions, and some of them become research questions. Then there’s a new project for a student that we can evaluate. Sometimes that project may take place at our facility. Other times, it can take place overseas. We’re at the very beginning of a very dynamic phase of opportunity.